Presented by Oaks Overhead Doors Co., Richmond, TX

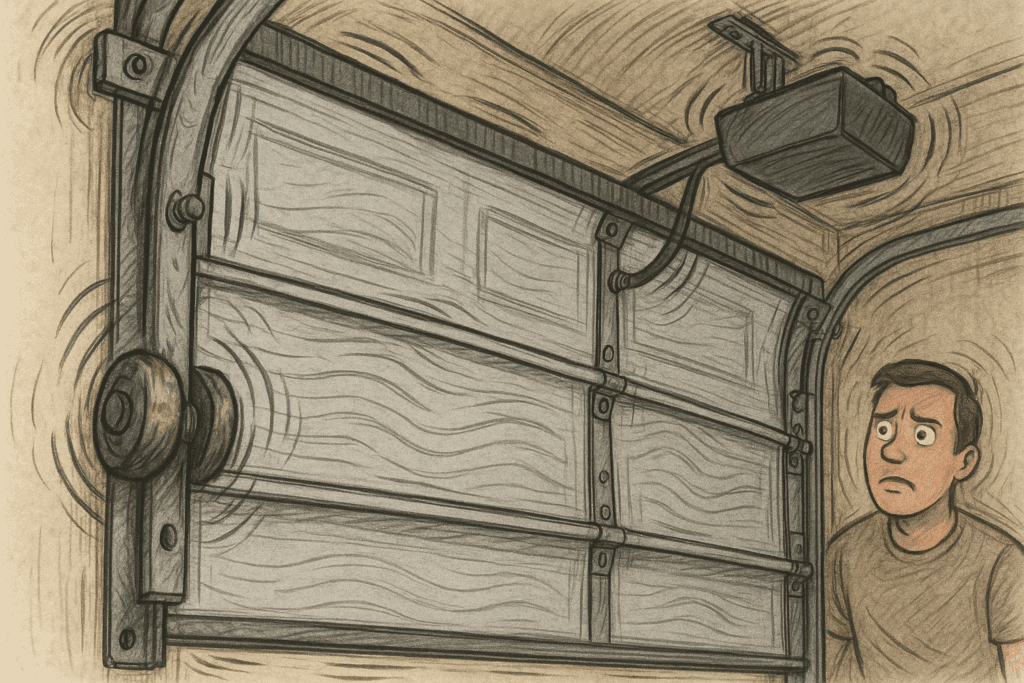

A recent call from a concerned homeowner in Richmond painted a clear picture of how easily garage door issues can escalate. One morning, while heading out for work, she heard a loud grinding noise. Her garage door had jammed mid-operation, and the opener strained to move it. Upon arrival, our technician found that the rollers had deteriorated and the hinges were nearly disconnected. While we were able to provide immediate garage door repair, this incident could have been avoided with routine maintenance. This case underscores the importance of staying ahead of potential failures with timely inspection and professional service.

This case is not uncommon. According to the U.S. Consumer Product Safety Commission, over 20,000 garage door-related injuries occur each year in the United States. Many of these are tied to faulty components such as rollers, hinges, cables, and springs. For Richmond homeowners, understanding the early signs of garage door issues is not just a matter of convenience but of home safety. Timely service can prevent costly repairs, extend the life of your garage door system, and ensure reliable operation.

If you are wondering when to repair garage door rollers and hinges, this guide is designed specifically for you. At Oaks Overhead Doors Co., we serve the Richmond area with comprehensive garage door services, including garage door opener repairs, spring replacements, custom installations, and preventative maintenance. In this article, we will walk you through what you need to know to keep your door running smoothly. From technical insights to actionable tips, we aim to equip you with everything needed to make informed decisions about garage door maintenance.

Understanding Garage Door Rollers and Hinges

Garage doors function through the coordination of several mechanical components, among which rollers and hinges play a vital role. Rollers are wheel-like parts that move within the metal tracks, allowing the garage door to glide up and down with ease. They are often made from steel, nylon, or plastic and are attached to each side of the door panels. Higher-quality rollers include ball bearings that reduce friction and noise during movement.

Hinges, on the other hand, are the metal joints that connect the different panels of the garage door. These components allow the panels to flex as the door curves along the track. Depending on their placement, some hinges also house the roller stems. Most hinges are numbered to indicate their position on the door, with lower-numbered hinges placed at the bottom and higher numbers going up the door. Understanding these numbers can be helpful during maintenance and replacement.

The importance of rollers and hinges cannot be overstated. They ensure the stability, alignment, and quiet movement of your garage door. When functioning correctly, they reduce strain on other parts like the springs, opener, and cables, helping to prevent widespread damage. Overlooking wear in these parts can put pressure on the door tracks and cause additional components to fail, ultimately affecting the entire garage door system.

Common Signs That Garage Door Rollers Need Repair

Rollers are essential to the movement of the garage door along the tracks. When they start to fail, you will likely notice several performance issues. Recognizing the signs early can help you avoid bigger problems and more costly repairs.

Unusual Noises: A noisy garage door often signals worn or dry rollers. Grinding, squeaking, or rattling sounds during operation indicate that the rollers may no longer rotate smoothly. Steel rollers can become especially loud when the bearings fail. This sound is more than a nuisance—it is an early warning sign that the rollers are no longer functioning efficiently.

Jerky or Stiff Movement: A garage door should operate smoothly. If it begins to vibrate, wobble, or stutter as it opens or closes, it may be due to rollers that are misaligned, cracked, or deteriorating. Jerky movement not only causes frustration but can also damage the tracks, opener arm, or torsion spring system.

Visible Wear or Cracks: During a visual inspection, you might notice rollers with flat spots, chips, or visible wear. These physical defects disrupt the motion of the door and can lead to track damage if ignored. In severe cases, the roller might even pop out of the track, creating a serious safety issue.

Door Derails from Track: If the garage door slips out of its track, faulty rollers may be to blame. Misguided rollers create unsafe operating conditions and require immediate garage door repair to prevent injury or property damage. Homeowners should never attempt to force a door back into its track without understanding the underlying issue.

Excessive Vibration: As rollers deteriorate, they create friction and instability. The resulting vibrations can be felt through the structure of the garage. This kind of movement may seem harmless at first, but it wears out mounting hardware and puts stress on the opener’s motor.

Indicators That Garage Door Hinges Need Replacement

Hinges allow the door panels to bend and flex as the door follows the curvature of the tracks. When hinges weaken or fail, the system’s structural integrity is at risk. Here are signs to check:

Cracked or Broken Hinges: Hinges under metal fatigue or strain may crack or break completely. This results in uneven panel movement and can increase stress on springs and cables. When a hinge breaks, the affected section of the garage door becomes unstable and may twist or sag during operation.

Loose Screws or Hardware: Screws and bolts that constantly come loose or strip the wood or metal around them may point to failing hinges. If hinges cannot hold the panel firmly, door alignment issues can develop. Pay close attention to hinge areas where screws have been overtightened or where the metal has become warped.

Panel Misalignment: Bent or damaged hinges can cause panels to sag or sit unevenly. This misalignment puts stress on the door tracks and can cause further component damage. Misaligned panels often scrape against the track or frame, leading to premature wear.

Unusual Noises at the Panel Joints: Creaking or clunking noises between panels may indicate that the hinge is no longer holding properly, often due to rust, debris, or wear. Proper lubrication can mitigate some of these noises, but if they persist, replacement is likely necessary.

Difficulty in Door Movement: Hinges play a key role in the articulation of the garage door. When they are compromised, you may notice resistance in door movement, uneven bending at the joints, or the door catching midway.

Why Richmond Homes Are Vulnerable to Roller and Hinge Issues

Several factors contribute to faster wear and tear on garage door components in Richmond, Texas. Understanding these local influences can help homeowners take preventive measures and make more informed maintenance decisions.

Frequent Usage: Many Richmond residents use their garage as the primary home entry, sometimes operating their garage door system multiple times a day. Frequent use leads to quicker deterioration of rollers, hinges, and springs. In high-use households, the garage door may operate 2,000 to 3,000 cycles annually, significantly above the national average.

Extreme Texas Weather: The high heat and humidity levels in Texas can lead to thermal expansion of metal parts, rusting of steel components, and drying out of lubricants. This weather-induced stress accelerates wear and reduces the efficiency of rollers, cables, hinges, and other garage door parts. Garage door openers can also struggle in extreme heat, particularly when components expand or contract.

Lack of Preventive Maintenance: Without routine inspections, lubrication, and adjustments, garage door components are more likely to develop hidden issues. What begins as a simple hinge squeak can evolve into complete door failure. Regular maintenance prevents small issues from escalating into full-blown repairs.

Poor Initial Installation or Materials: Some garage door companies use subpar materials or skip essential installation steps. Low-quality rollers and hinges fail faster, especially in the demanding climate of Richmond. Opting for garage door companies that use commercial-grade parts and professional installation methods can mitigate these risks.

DIY Inspection Checklist for Richmond Homeowners

Performing regular maintenance and inspections can prevent minor issues from becoming costly garage door repairs. Use this checklist to evaluate the condition of your rollers and hinges:

- Visual Scan: Inspect all rollers for signs of cracks, chipping, or distortion. Examine hinges for rust, bending, or missing screws. Look for signs of wear on the tracks and signs of stress near mounting points.

- Manual Door Test: Pull the emergency release and manually lift the door. It should move with consistent resistance. Any stiffness or sudden jerks point to an issue. If the door feels unbalanced, the torsion or extension spring system may need professional adjustment.

- Noise Observation: Operate the door while listening for squealing, grinding, or banging. These sounds often indicate roller or hinge distress. Consistent loud noises from the same area of the door usually suggest a localized issue.

- Check All Fasteners: Tighten any loose screws, bolts, or lag screws. Be cautious when dealing with high-tension components like springs and cables. Use the appropriate tools to avoid stripping or damaging the hardware.

- Lubrication: Apply silicone-based lubricant to rollers, hinges, and moving parts. Avoid oil-based products that attract dust and debris. Lubricating the rollers and hinges every three to six months can extend their lifespan and improve performance.

- Track Alignment: Inspect the vertical and horizontal tracks to ensure they are properly aligned. Misaligned tracks can cause the rollers to bind, resulting in jerky movement and increased wear.

If your inspection uncovers any of these signs, it may be time to call a local garage door professional to assess and repair garage door components.

When Should You Repair or Replace Garage Door Rollers and Hinges?

Rollers and hinges have specific life cycles based on material and use. However, certain situations require immediate attention. Being proactive about replacement can save you from more significant mechanical problems and higher costs.

- Nylon Rollers: These typically last 5 to 7 years with regular use. Look for visible wear, noise, or operational stiffness. Although nylon rollers are quieter, they tend to degrade faster in high-temperature environments like Texas. Choose rollers with sealed ball bearings for enhanced durability.

- Steel Rollers: More durable than nylon, steel rollers can last up to 10 years but may become noisy if bearings wear out. They are better suited for commercial garage doors or homes with heavy-duty systems. However, they require regular lubrication to prevent corrosion.

- Garage Door Hinges: Inspect annually and replace them if you see visible rust, cracking, or warping. Hinges under heavy daily use may wear out in under 5 years. If your garage door is making popping or creaking sounds while in motion, it’s time for a closer inspection.

Always act quickly when warning signs emerge. Waiting to repair garage door parts increases the risk of total door failure, higher repair costs, and potential injury. A simple hinge replacement today can prevent track damage and door misalignment in the future.

The Importance of Professional Garage Door Service

While some inspection and lubrication steps can be done at home, most garage door repairs should be handled by trained professionals. Here is why relying on experts is not just recommended but necessary.

Safety: Garage doors are heavy and often contain high-tension components like torsion springs and cables. Mishandling these parts can cause serious injury. Professionals understand how to release tension safely and handle components that can be dangerous when improperly accessed.

Proper Tools: Professionals have access to specialized tools that allow for precise alignment, tension adjustment, and component replacement. These include winding bars, alignment gauges, and torque wrenches that are essential for fine-tuning a garage door system.

Quality Parts: Local garage door companies like Oaks Overhead Doors Co. use commercial-grade rollers, hinges, tracks, and garage door openers that last longer and perform better. This ensures that every repair contributes to long-term performance and fewer call-backs.

Correct Installation: Improper installation of rollers or hinges can cause misalignment or worsen existing issues. Professional service ensures every part fits and functions properly. A misaligned roller, for example, can cause the opener to overexert, leading to motor burnout.

Time and Cost Efficiency: While DIY repairs may seem cost-effective, they often lead to mistakes that require additional service. Expert work gets the job done right the first time, saving both time and money. Consider the value of your time and the potential cost of replacing an entire garage door system due to overlooked damage.

Customized Solutions: A professional can assess your specific garage door system and suggest upgrades or reinforcements suited to your usage habits, climate conditions, and long-term goals. From new garage door opener models to energy-efficient insulation upgrades, expert guidance ensures optimal performance.

Benefits of Timely Garage Door Repairs

Proactive repairs and maintenance offer numerous advantages beyond just function. Here are several benefits Richmond homeowners can expect when they address garage door issues early:

- Smooth Operation: Replacing worn rollers and hinges reduces friction and noise, creating a more pleasant experience. This is especially important for attached garages where noise can disturb living spaces.

- System Longevity: Keeping all components in top condition extends the life of your garage door system and delays the need for a new door. Well-maintained rollers reduce strain on cables, springs, and openers.

- Lower Utility Bills: A garage door that closes tightly and functions efficiently helps maintain internal temperature, boosting energy savings. This is particularly crucial if your garage is insulated or houses temperature-sensitive equipment.

- Enhanced Home Safety: Preventing door malfunctions protects your vehicles, family members, and home valuables. A falling or misaligned door can cause injury or damage property. Timely repair minimizes these risks.

- Increased Property Value: A well-maintained garage door adds curb appeal and reassures potential buyers about home upkeep. A quiet, functional, and visually appealing door reflects well on your entire property.

- Reduced Emergency Repairs: Addressing small issues early can prevent emergency garage door breakdowns during inconvenient times, such as late nights, holidays, or extreme weather events.

Myths That Mislead Homeowners

There are several misconceptions about garage door systems that can lead homeowners to delay or ignore necessary repairs. Let’s debunk a few of the most common myths.

Myth 1: A Noisy Garage Door Is Normal

Truth: Persistent noise signals an issue. Ignoring it allows small problems to grow. Normal operation should be quiet and smooth. If your door has become loud over time, it’s a sign that maintenance is overdue.

Myth 2: Only the Opener Matters

Truth: The opener is only one part of a larger system. Failing rollers or hinges can prevent the door from working even with a functioning opener. Garage doors rely on coordinated movement between all components. A weak hinge or broken spring can halt everything.

Myth 3: Repairs Can Wait Until Something Breaks

Truth: Waiting can cause secondary damage to cables, tracks, springs, and the opener, resulting in more costly repairs. Preventative garage door maintenance costs far less than emergency repairs or full system replacements.

Myth 4: All Garage Door Parts Are the Same

Truth: Not all rollers, hinges, or openers are created equal. There are significant differences in material quality, load capacity, and lifespan. Using premium-grade parts improves safety and performance.

How Can Oaks Overhead Doors Co. Help You?

At Oaks Overhead Doors Co., we are proud to be the undisputed industry leader in garage door service in Richmond, TX. Our top-tier team of expert technicians is fully trained to identify, repair, and prevent all types of garage door issues, including problems related to rollers, hinges, springs, cables, garage door openers, and tracks. With years of hands-on experience and cutting-edge training, we deliver results that are safe, reliable, and built to last.

Our services include:

- Emergency garage door repair appointments available when you need us most

- Thorough inspections and preventative tune-up services for residential and commercial doors

- Replacement of high-tension components like garage door springs and extension cables

- Professional garage door opener installation, calibration, and troubleshooting for all brands

- Custom hardware upgrades for quieter, smoother, and more efficient garage door operation

- Free quotes, honest reviews, and upfront pricing with no surprise fees

Whether you are dealing with a noisy garage door, worn hinges, or cracked rollers, our team is ready to restore your garage door system to peak performance. We serve homes and businesses throughout Richmond, including Long Meadow Farms, Harvest Green, and Pecan Grove.

Location: 7119 FM 1464, Richmond, TX 77407, United States

Phone: (281) 572-5318

Call us today to schedule a free quote or inspection and discover why Richmond homeowners trust Oaks Overhead Doors Co. for all their garage door maintenance and repair needs.

Final Thoughts

Garage doors are a vital part of your home’s safety, comfort, and efficiency. From allowing easy access to protecting your property, they perform a heavy-duty job every single day. Recognizing the signs of wear in components like rollers and hinges is essential to avoiding garage door problems that can escalate quickly. Routine maintenance, quick repairs, and professional service go a long way in extending the lifespan of your garage door system.

By following the insights in this guide, Richmond homeowners can take proactive steps to avoid emergency garage door situations, improve energy efficiency, and keep their doors operating smoothly. Investing time in inspections and repairs today ensures long-term performance and safety for years to come.

If you are unsure where to start or need a second opinion, do not hesitate to reach out to Oaks Overhead Doors Co. Our experienced technicians are here to guide you every step of the way, from diagnosis to full repair. Let us help you maintain a high-functioning, dependable, and safe garage door system for your home.

Frequently Asked Questions (FAQs)

1. How often should garage door rollers and hinges be lubricated?

Garage door rollers and hinges should be lubricated every 3 to 6 months using a silicone-based lubricant. Regular lubrication helps reduce friction, minimize noise, and extend the life of these moving parts.

2. Can I replace garage door rollers and hinges myself?

While experienced DIYers can replace rollers and hinges, it’s not recommended due to safety concerns. Garage doors involve high-tension components, and improper handling may lead to injury or further damage.

3. What type of rollers are best for quiet garage door operation?

Nylon rollers with sealed ball bearings are ideal for quieter garage door movement. They reduce noise significantly compared to steel rollers and require less maintenance.

4. Do garage door hinges come in standard sizes, or do they vary?

Garage door hinges are not one-size-fits-all; they vary by placement and panel configuration. Each hinge is typically numbered, and using the wrong size or type can lead to alignment issues and improper door function.